| www.dcengineering.co.uk - specialist dairy engineers and milking machine installers |

|

Home |

Outdoor

Directory |

DCE services | DCE Products |

Enquiries | Links | Second Hand |

News | DeLaval Parlours |

Weather

|

|

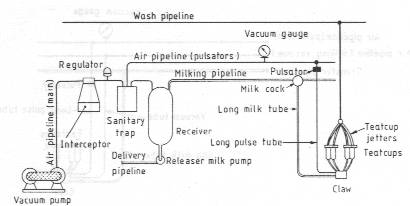

This type of parlour works as it's name suggests. The milk comes from the cow into the cluster, and goes direct to the milk line. The milk line is sloped from a high point to the milk receiver jar with a slope of 25mm per 3m run. Once in the milk line, it flows under gravity into the receiver assembly. In a direct to line system, the pipeline serves the purpose of providing the milking vacuum and milk transport in one line. The milk flows along the bottom of the pipe, with the vacuum above it.

The early direct to line systems were made with glass milk lines, with an external dimension of 1 1/4" (32mm) and an internal dimension of 1" (25mm). The system is very simple to install and maintain, and has a very small surface area, meaning sterilisation and hygiene are easy to control. There are very few restrictions between the line and the cluster assembly, so air flow and vacuum stability are very good compared with the recorder milking machine.

This system worked well, until the yields from the cows increased to the stage that the line was flooding, causing the pipe to fill with milk, the vacuum level behind the blockage to drop, and giving clusters less vacuum until the blockage was sucked into the receiver jar.

As it should be. Vacuum (green) over the top of milk (blue). This gives a nice steady vacuum to the cluster.

All is not well. A slug of milk blocks the pipe, leaving no way for the vacuum to get from the end of the pipe. The green area to the right shows an unstable vacuum.

The modern day

system typically uses a 3" ( 76mm) external diameter 2 7/8" (75mm)

internal diameter stainless steel milk line, which due to its much larger

diameter, has the effect of giving a much higher reserve of vacuum, and allows

the pipeline to hold a higher capacity of milk before the line floods.

The modern day

system typically uses a 3" ( 76mm) external diameter 2 7/8" (75mm)

internal diameter stainless steel milk line, which due to its much larger

diameter, has the effect of giving a much higher reserve of vacuum, and allows

the pipeline to hold a higher capacity of milk before the line floods.

The disadvantages of this type of system are not being able to see the amount of milk each cow gives per milking, (except if you have full time milk meters) , and there is a higher chance of contaminated milk entering the bulk milk tank.

|

|

Copyright dc engineering 1987-2007. All copyrights, trademarks, service marks, and logo's are the respective property of their holders. This site may not be copied without the written consent of dc engineering. All text that is intellectual property is copyrighted. Images and our Logos are copyrighted and may not be reproduced in any way without the written consent of dc engineering. This site is maintained by