| www.dcengineering.co.uk - specialist dairy engineers and milking machine installers |

|

Home |

Outdoor

Directory |

DCE services | DCE Products |

Enquiries | Links | Second Hand |

News | DeLaval Parlours |

Weather

|

|

[ALPRO System] [ALPRO Activity Meter] [Maestro for ALPRO]

DeLaval's philosophy is that a feeding system should be designed to suit the cows, instead of the other way around. In this manner feeding can be carried out effectively and the cows will be healthier, which creates the conditions for good profitability. When the ALPRO Feeding System was designed, DeLaval called upon it's extensive experience and high technology standards to adapt the system to suit the natural behaviour of the cows, both individually and in groups, in a way that is totally unique.

The ALPRO feeding system continuously ensures that each cow is fed the correct feed and ration. The available quantity of feed is adjusted to the length of time since the last visit to the feeding station. A cow can never eat more than a certain programmed portion of the daily ration at one time.

Research has shown that the feeding station helps cows follow their own behavioural patterns. Their daily ration is spread over approximately ten visits per day. There are no rush hours to feed stations. When feeding is rationed and spread over a period of time, the acidity of the cows rumen stays normal. The cows feel better in themselves and feed utilization increases.

If a cow does not eat its entire ration in the 24-hour period, the remaining portion is carried over to the next daily ration. If the cow consumes less than the pre-programmed daily percentage, a warning will show automatically. A warning signal will also be shown if a cow eats less than the preselected daily percentage of her ration for three days in a row.

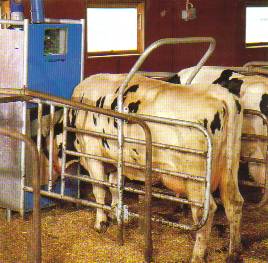

The ALPRO system's ability to continuously proportion feed is unique. The feed trickles down into the manger at the same speed as the cow eats. The dispensing rate can be adjusted for each animal, depending on her eating speed. The dispensing stops as soon as the cow takes her head from the manger. It is therefore useless for a cow to push another away from the feeding station, as no food is left in the manger after a cow has finished. The result will be the correct reporting of feed intake and the cows will be calmer around the feeding stations.

Feeding stations in the ALPRO system have a capacity for four different feeds. The stainless steel manger is specially designed to let a cow eat comfortably, at the optimal speed. The feeds are also mixed in a controlled fashion so the cows will eat all varieties instead of selecting the ones they like best.

The feeding stations have a robust construction and are built for tough use indoors, as well as outdoors under a roof. Sturdy galvanized pipes protect the electronics and feed dispensers in the station. Strong side rails and a rear support ensure that the cows stand calmly and protected while they eat.

Dispensers can also be connected to the system for easy control of automatic feeding in the parlour. When linked with automatic identification the operator can dedicate his time to the milking work. The ALPRO system keeps record of all feed intake for presentation on screen or printouts, or for more accurate determination of margin over concentrate, per cow or for the whole herd.

During a busy work day, the scheduled feeding of your calves adds extra

stress. We also know from research that an adult cow's chances to achieve high

productivity are determined from the very first day of life. That's why DeLaval's automatic milk feeder and concentrate feeding station for calves are

important components that can be built into the ALPRO System to give you

complete control over your animals from the start.

During a busy work day, the scheduled feeding of your calves adds extra

stress. We also know from research that an adult cow's chances to achieve high

productivity are determined from the very first day of life. That's why DeLaval's automatic milk feeder and concentrate feeding station for calves are

important components that can be built into the ALPRO System to give you

complete control over your animals from the start.

The calf feeder automatically mixes the milk replacer and water. Fresh or sour milk can also be dispensed in the combi version. The calves always receive milk, in the correct concentration, at the correct temperature, in small rations over the day. Since the automatic feeder is connected to the ALPRO system, you will be quickly warned if one of the calves is not feeding properly.

With the automatic feeder, calves develop steadily into a ruminant without growth breaks. The ALPRO system will automatically indicate the calves that have managed to be weaned and those having problems.

DeLaval's

feed wagons can be connected to the ALPRO System for more efficient and

controlled feeding of cows in stanchion barns. With this arrangement, cows can

receive feed up to ten times a day. Their milk production will increase as a

result, and time will be saved.

DeLaval's

feed wagons can be connected to the ALPRO System for more efficient and

controlled feeding of cows in stanchion barns. With this arrangement, cows can

receive feed up to ten times a day. Their milk production will increase as a

result, and time will be saved.

Studies of manual feeding have shown that dairy farmers often give cows a little extra feed to be sure they get enough. It has been found that up to 10% overfeeding is quite normal.

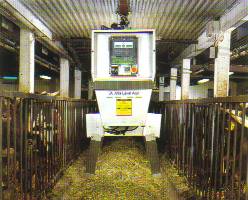

The automatic feeder basically functions as a feeding robot. When the feeder is in the parked position, the processor gives it instructions. The feeder then moves out on rails, stops at the set markers and dispenses the correct ration of feed. When the feeding is finished, it reports back to the processor.

The feed wagon can also be used for automatic feeding of heifers and young animals. The feeder will save a lot of labour, especially now it is offered in a stand-alone system. All programming and follow-up is handled easily from the processor, where you can access all practical breeding functions, do feed calculations, and get status printouts.

|

|

Copyright dc engineering 1987-2007. All copyrights, trademarks, service marks, and logo's are the respective property of their holders. This site may not be copied without the written consent of dc engineering. All text that is intellectual property is copyrighted. Images and our Logos are copyrighted and may not be reproduced in any way without the written consent of dc engineering. This site is maintained by